- Home

- About Us

-

product

- Colour

- Black

- White

-

additive

- Anti-Slip Masterbatch

- Conductive Compounds

- Optical Brighteners

- Desiccants (Moisture Absorption)

- Flame Retardants Masterbatch

- Anti-microbial Masterbatch

- Nucleating/clarifier Additives

- Anti-statics Masterbatch

- Anti-block Masterbatch

- Polymer Processing Aids (PPA)

- Antioxidant Masterbatch

- Bio Digradeble Masterbatch

- Customised Additive

- special master batch

- application

- Quality

- Downloads

- Career

- Why Us?

- Contact

Sheet Extrusions

Sheet extrusions involve feeding plastic material through a heated barrel, where it's melted and then forced through a die to create a continuous, flat sheet of plastic. This versatile method enables the creation of various plastic sheets with different thicknesses, widths, and properties, tailored to specific applications. These sheets find utility in an array of industries, including packaging, automotive, construction, and signage.

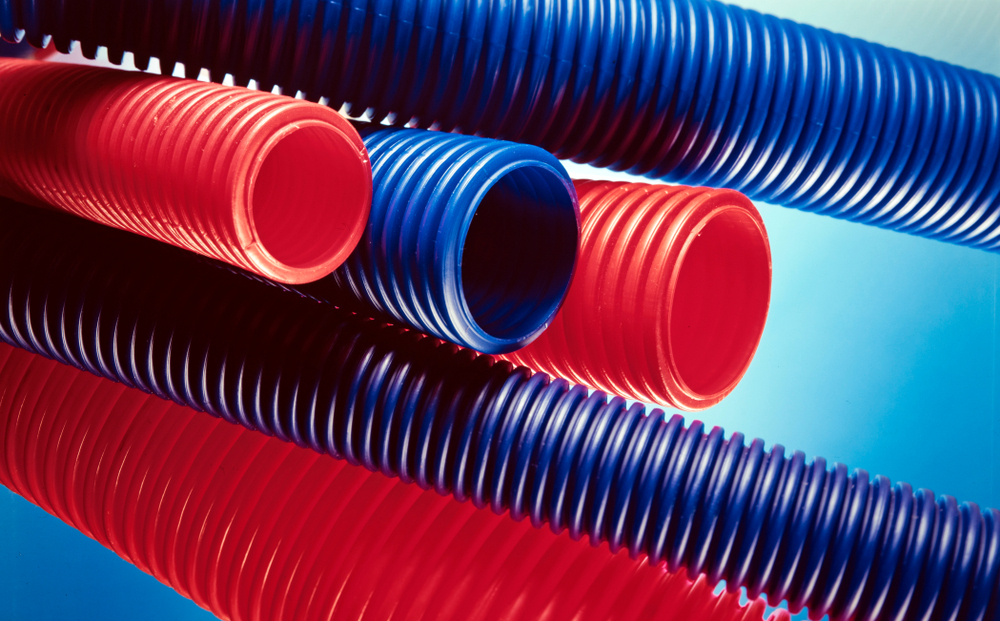

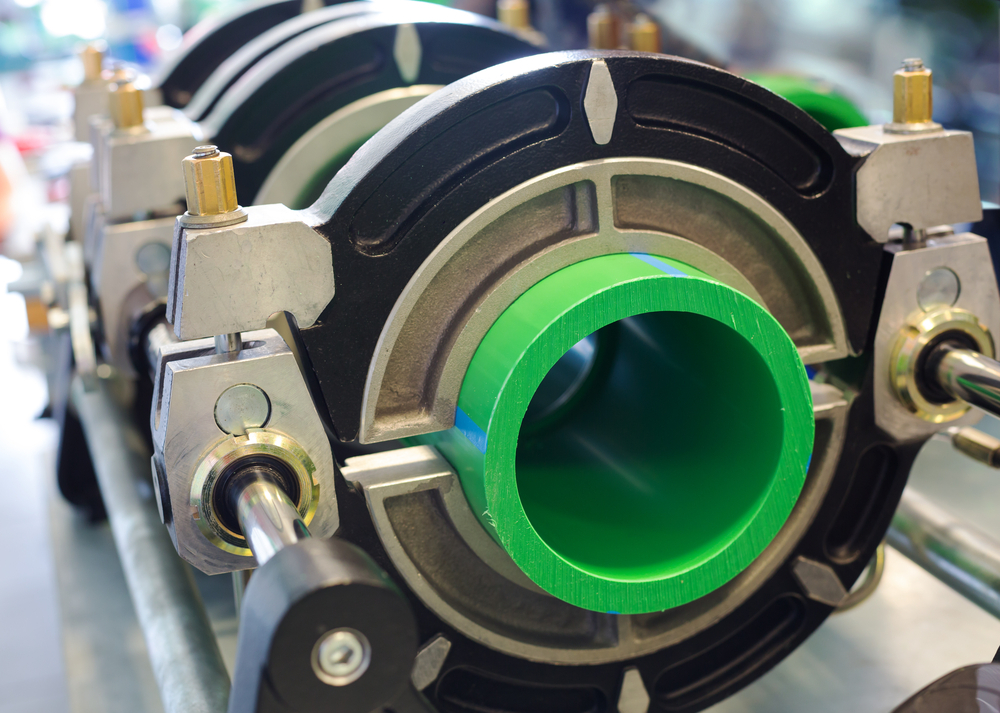

Pipe Manufacturing

Pipe manufacturing entails a similar process, but with a focus on shaping molten plastic into cylindrical tubes. Pipes serve as essential conduits for transporting liquids, gases, and solids in numerous sectors such as plumbing, irrigation, industrial processes, and utilities. The extrusion process allows for the production of pipes with diverse diameters, wall thicknesses, and materials, meeting the demands of different environments and operational requirements.

Both sheet extrusions and pipe manufacturing rely on advanced machinery, precise temperature control, and specialized tooling to ensure consistency and quality in the final products. These processes play indispensable roles in modern manufacturing, offering solutions for a myriad of industrial and commercial needs.